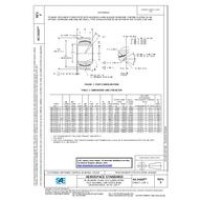

This test method is intended for measuring fuel permeation at elevated temperature through low permeating hose or tubing samples of elastomeric or composite construction. The expected accuracy of the method is about +/-10% of the sample permeation rate.Hose permeation testing can be done two ways: Method A - Plug and Fill or Method B - using a fuel reservoir.Method A involves plugging one end of the hose, filling the sample to about 90% full with test fuel, plugging the other end, and then exposing the plugged sample to a desired test temperature, with the weight loss measured over time.Method B involves plugging one end of a hose, and then connecting the other end to a fuel reservoir. The hose sample and reservoir are then exposed to a desired test temperature with the weight loss measured over time.This procedure presents a recommended plug design that permits inserting the plugs prior to adding the test fluid. One of the plugs has a small fill hole with a gasketing system that insures low permeation. This design prevents assembly problems created by pressurizing a fuel filled configuration, when inserting plugs with high insertion forces.Method A is intended for samples with low surface to volume ratios, so that the % fuel loss over the test period is low, and the resultant fuel compositional change does not significantly affect the permeation rate (typically less than 10% fuel loss for CE10 fuel). Method B should be used when fuel loss with Method A would be too large. This is typically done where hoses are small diameter (less than 18 mm) and have high permeation rates. The size of the reservoir chosen for Method B depends on the permeation rate of the sample and should be large enough to assure that fuel loss over the test period is less than about 10%. The amount of fuel loss that might be acceptable will depend on the fuel composition and the type of material tested. Uniform deviations from linearity of the weight loss versus time curves that are not a result of changes in environmental conditions such as temperature should be considered suspect regions and could be a result of compositional or configurational changes might be affecting the permeation rate.Standard permeation test temperatures are 40 degrees C and 60 degrees C. Standard test fuels are Fuel C and Fuel CE10. Other fuels, such as Fuel CM15, and other volatile liquids may be tested according to this procedure as desired. The method is not applicable for measuring permeation of higher boiling materials that will not completely evaporate from the exterior sample surface at the test temperature.

PDF

PDF

All of our standards document are available in PDF (Portable Document Format), an electronic, downloadable format.You will be able to download the file in your account downloads.

Multi-User Access

Multi-User Access

After purchasing, you have the ability to assign each license to a specific user.

Printable

Printable

At any time, you are permitted to make printed copies for your and your members' reference use.

PDF

PDF

Multi-User Access

Multi-User Access

Printable

Printable